Folding ladder made of wood with their own hands according to the drawings

Making step-ladders is quite accessible to home craftsmen who have at their disposal a standard set of tools and basic skills of assembling wooden structures. Portable folding ladder for the garden, cottage and private home - hand-assembled stepladder is made from quite accessible wood after simple preparation.

To ensure safety and longevity of use we recommend the use of ready-made step-ladders from DIRS plant.

Contents

- Types and designs stepladders to assemble their own hands

- What kind of wood is better to make with their own hands stepladder ladder

- Stepladder stepladder dimensions to make with their own hands according to the drawings

- Sizes and drawings for folding step-ladder

- How to make a step-ladder with your own hands

Types and designs stepladders to assemble with their own hands

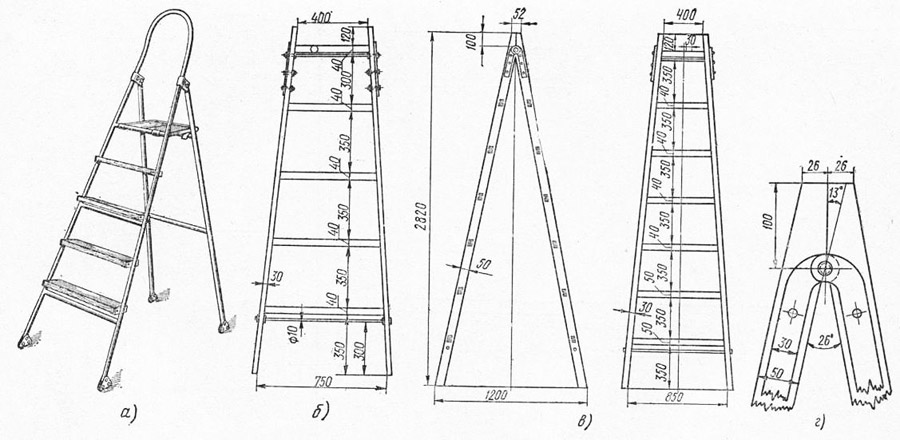

How to make a stepladder from ready-made bars with a simple set of tools? Let's understand the nuances and first choose the type of ladder that suits us best. There are few types of stepladders, but according to ready-made drawings stepladders can be quite an idea of them.

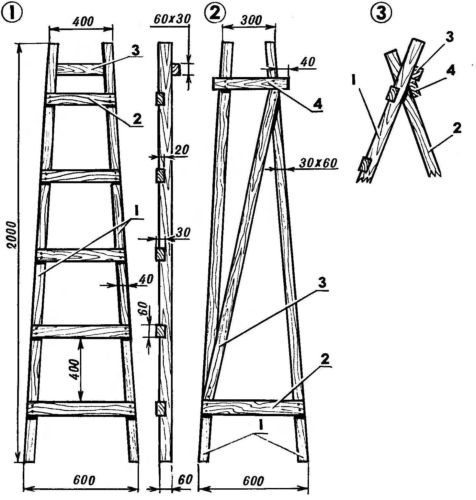

1. Let's make a stepladder out of a log. - A common solution suitable for apartments, summer cottages, and work in the field. The drawing shown shows that it is a tapered ladder with rungs at the top, supported on the back side. When stored, it takes up little space, is easy to carry, maintains stability on a flat surface. Made by your own hands stepladder of this type will freely withstand a weight of up to 110-120 kg (depending on the quality of the wood).

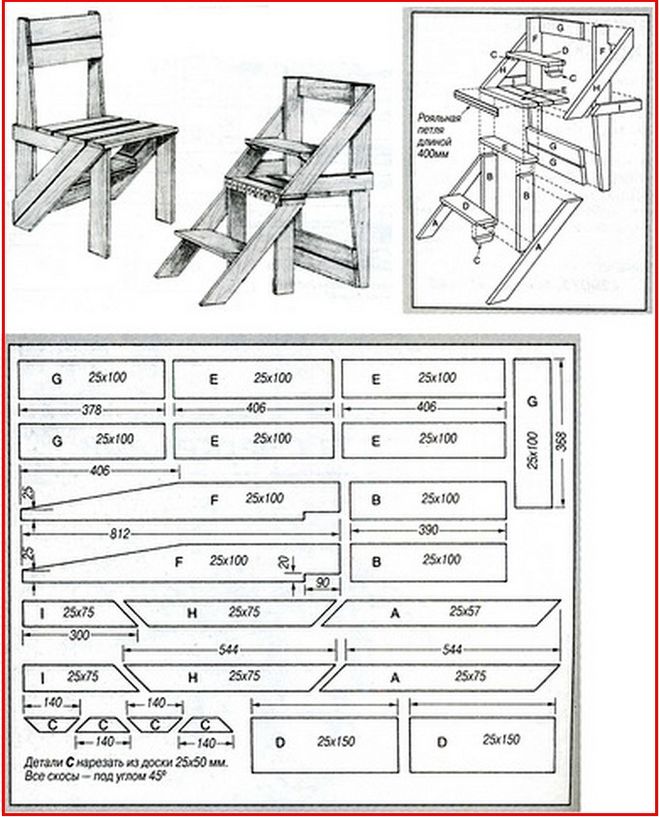

2. Homemade step-ladder chair - A sturdy, stable support that can be transformed into a comfortable seat and used indoors to climb to a height of up to 1.5 meters.

The idea is good, but it is not a ladder in its pure form, but rather a multifunctional household item. It has good stability, but it weighs more than a ladder and takes more space. You cannot hang it on the wall.

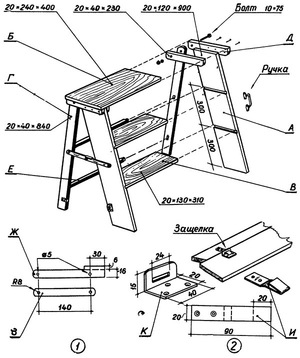

3. a wide stepladder stand or shelf. Suitable for dachas and apartments, if you are ready to build into the interior of the device on which you can and arrange objects (jars, pots with flowers), and if necessary to arrange for repairs in the room.

Such a stepladder with their own hands takes up space, becomes part of the furnishings, but it can also be folding. If you look closely at this drawing of a wooden stepladder, you can find knots of joints suitable for the installation of hinges and hinges.

4. A stepladder with a platform is a modification of the stepladder-stool, on which it is convenient to stand.

The drawing of the stepladder in the form of a bollard or chair on struts will tell you how best to prepare the material.

This solution is suitable if you do not seek to make a wooden stepladder with their own hands necessarily folding, counting on it as part of the situation, for example, on the balcony, in the household room, in the country house.

Depending on what type of stepladder ladder you have chosen, you should form a set of bars, boards, fasteners, hinges and other parts.

What kind of wood is better to make a stepladder ladder with your own hands

Let's start with the materials. A stepladder made of wood with their own hands should be lightweight, strong and able to withstand variable loads.

Making stepladders in the conditions of the home workshop means that you will have a purchased material in the form of a bar.

In terms of value for money and the quality of the wood:

- Pine - lightweight, resinous, soft to handle and medium tough structurally, almost impervious to rot if treated properly, cheap;

- Spruce - similar to pine, is inexpensive, but when choosing a spruce beam should be carefully studied each billet, as spruce is knotty, it is not allowed in the manufacture of stringer and rungs stairs;

- Larch - like all conifers, it does not rot, but its wood readily absorbs moisture, which means that over time it is likely to warp the bowstrings and ladders;

- Aspen - dense, heavy, does not rot, but it is difficult to handle, although with the skills and quality tools perfectly suited for step-ladders with stringer blocks over one and a half meters high.

- How to make the step-ladder with your own hands strong and mobile? To do this, you will need to pick up a tool for good processing of the joints of the parts and fittings - hinges and hinges. In the simplest solution, the hinges can be replaced by studs with washers and fixation on the clip.

Stepladder dimensions for making ladders with their own hands according to the drawings

The dimensions of the stepladder with their own hands are selected either strictly according to the drawing, or individually. Basically, the difference will only be the length of the bars.

In order to choose the right material, you need:

- Decide on the design - folding, ladder, stepladder chair or stepladder, bollard;

- Choose the size of a wooden stepladder for the main parameter - the height, which depends on the ratio of other parts;

- Make a simple calculation of the length of the bar on the stringer, rungs, stops, if you do stepladder ladder

- To make the calculation of the number of steps, rungs and platforms, taking into account the final height.

These features should be considered separately, for examples. Wooden stepladder with their own hands in the form of a folding ladder is made of timber:

- for the stringer and back stop will need a bar without knots section of 60x40 and length depending on the height of the ladder;

- For rungs we will need a bar without knots 60x30 with length according to the number of steps;

- The length of each rung, as in the drawing of the stepladder from a tree, is specified conditionally, only for the case if you strictly follow the instructions;

- When unfolded, the step of the stepladder (distance from the stringer to the rear footing) should be approximately 50-70 cm, depending on the height of the ladder;

- The distance between the stringer stringer legs at the bottom - 60 cm, at the top - 40 cm.

We should separately mention the calculation of the number of steps and the choice of the final height of the ladder stepladder.

Dimensions and drawings for a folding step-ladder

Wooden step-ladder with their own hands should be made safe and convenient for climbing and descending.

Optimal criteria for the placement of the rungs:

- The height of the platform of the first step from the floor - 35 - 40 cm, taking into account the height of the normal step;

- the distance between the rungs of the step-ladder (from the platform to the platform) - at least 30 cm;

- rungs should not overlap each other from top to bottom, so that you do not miss a foot when descending and fell into the void;

- The optimal depth of the step of the ladder folding ladder - 6 cm;

- The slope of the steps (rungs) forward and backward is unacceptable - it is a high risk of slipping and falling.

How to choose the right steps for a stepladder

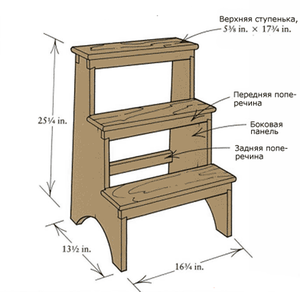

If you decide to make your own hands a stepladder made of wood in the form of a bollard, folding chair or a more complex transformer, then choose a design on struts. This is the name of the wide load-bearing sides of stairs. They work well as a base with a low center of gravity. The depth of the top step should be at least 10 cm, if you intend to put the bollard close to the wall during the work. This is why the strut and stepladder supports are made slightly protruding beyond the back edge of the top step. Ladder stepladder made of a lighter beam with an increase in width to 1 meter at the bottom can lose strength.

Stepladder height according to the drawings and in reality

How to make a stepladder of the correct and safe height? In general, the height of the ladder stepladder is 200 - 210 cm at the top, where the support connects to the stringer. The height of the last rung should be about 30-40 cm lower to keep the ladder stable. Functional height made with their own hands stepladder ladder will be approximately 150 - 170 cm. Higher - is risky, you can lose stability. Reach for the ceiling, a lamp, to hang a picture will get in any case.

How to properly make a stepladder with your own hands

Why have we paid attention to the step of the ladder and the location of the top step? Making a wooden stepladder ladder with your own hands, you must take into account several features of its design and subsequent use.

- Restriction on the height. A simple calculation of the application of forces on the rule of a triangle shows that if you climb on the site above 170 cm, the sum of your height and height will be critical for stability value. Raising your arms to work will cause you to lose your balance.

- The height of the stepladder to the top point (200 - 210 cm) allows you to create support for your shins and arms. If you attach an additional frame of light metal to the stringer, you can hold on to it or control your balance with your knees.

- Making stepladders according to the rules and drawings takes into account the ability to reach the wall. If the step of the step ladder is more than 70 cm, you will have to bend forward, extending your arms - this will lead to loss of balance.

- For work near the wall, it is better to prepare a stepladder on a bollard or stepladder on struts. It can be made a little wider than the ladder to move over a wide platform and not to lose balance.

Preparing materials and components for making a wooden stepladder with their own hands

Preparation of materials for assembling a stepladder from wood with their own hands includes the selection and pre-treatment of wood.

- The humidity of the wood should not exceed 12 - 15 %, otherwise your stepladder will become deformed, lose stability. Step-ladders on struts made of wet wood will sway with changes in humidity.

- The wood should be sanded, especially the beam that goes on the stringer and steps. The edges of the rungs should not be rounded or chamfered to keep your foot from slipping. The crossbars should not be coated with smooth lacquers and paints.

- Rubber shoes must be installed on the bottom ends of the stringer and the base of the step ladder. No polymers or slippery hard products should be used!

- The step-ladder with its own hands must be made with a reserve of strength and reliability. For this purpose, diagonal struts in the back are used. If you want to make a stepladder for full-length work, attach a platform of wood to the top step, which should rest on the rung at the side of the stop. The platform must lie strictly horizontally and not slip forward and backward - for this purpose the bar stops are made from the bottom.

- Connections of the stringboard, stringers and crossbars are made in a groove with at least 10 mm indentation from the edge. Mounting on carpenter's glue can be strengthened with a longitudinal stud or movable spacer.

- When building the stepladder with their own hands do not use wood with knots, it is brittle, under the load stringer or rung will break. Allowed only knots in stringer thickness of at least 30 mm.

To ensure safety and durability of use, we recommend the use of prefabricated stepladders from the DIRS factory.

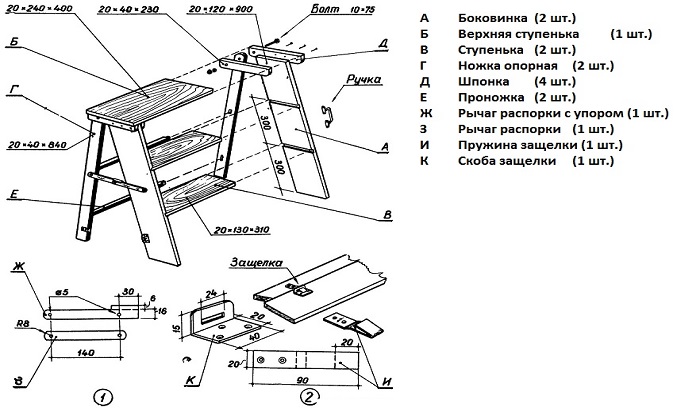

Presented here drawings for the assembly of the stepladder with their own hands - the best proven solutions. But you can choose your own size options, so the dimensions of individual parts, especially the length of rungs, stringer, height of struts may vary. Do not use a smaller beam thickness! - The construction will be fragile and unstable. Do not forget to stain the wood before assembly, so that it will last longer without rotting and absorbing moisture.